Types of Thermistors

In a previous blog we discussed what a thermistor is and how it works. We also examined what a resistor is because a thermistor is really just a special type of resistor. Let’s delve a little deeper into what different types of thermistors there are, what they are made from, and what sort of jobs they perform. If you haven’t yet read our introduction into thermistors, be sure to check out “What is a Thermistor” first, and then come back here to learn a little more about this intriguing temperature sensor.

Figure 1: 2.251K, 40K, and 10K thermistors

Thermistor basics

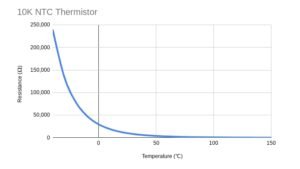

As discussed in our previous blog, a thermistor will resist electrical current. It differs from a resistor because a thermistor will affect the current depending on temperature. We won’t go through as many details in this article but click the link above to get that refresher. Let’s take a look at a chart to help visualize the link between temperature and resistance.

Figure 2: A 10K thermistor chart

You can see how the resistance of the thermistor decreases with an increase of temperature. If this was a chart for a resistor, the “curve” would actually be a vertical line; the resistance value would not change no matter the temperature. Resistors are great for use in electronics, for example, because of this stable characteristic. A 10K resistor will always restrict 10,000 ohms of an electrical current. A 10K thermistor, however, will only restrict 10,000 ohms of a current at 25℃. If the temperature is warmer, let’s say 50℃, the thermistor would restrict only 3,900 ohms. This variability with a change in temperature may make a thermistor terrible for use in electronics but it sure makes for a great thermometer.

Different Types of Thermistors

There are many different types of thermistors but they all work on the same principle: variable resistance based on temperature. There are basically two categories of thermistors of which all types fall under; NTC and PTC. Depending on your particular application you may opt for one thermistor over another. Let’s explore those two big differences first.

Negative Temperature Coefficient (NTC)

NTC thermistors are the most common type available for use. The defining characteristic of this thermistor is that its resistance decreases as temperature increases. These sensors are found widespread throughout the HVAC industry, product manufacturing, transportation, appliances, and many other sectors. By resisting current a thermistor creates the byproduct of residual heat. If an NTC thermistor will be known to operate in temperatures that will cause significant heat, a correction can be applied to sensed values to maintain accuracy. Also, with NTC thermistors, this self-heating effect will happen at low temperatures where it can dissipate much more readily into the surrounding process.

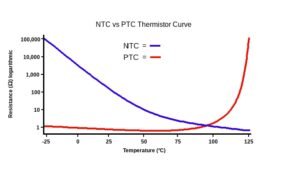

Positive Temperature Coefficient (PTC)

PTC thermistors act in the opposite way of an NTC thermistor. Positive Temperature Coefficient means that as temperature increases the resistance of the thermistor also increases. This category of thermistors is not common but they do perform a particular niche function; that of a safety fuse. In some processes the presence of excessive heat means an undesirable situation is occurring. If a PTC thermistor is present within a circuit it can act like a sort of throttle. The increase of resistance that comes with an increase in heat is like a natural safety valve and the circuit that is overactive will reach a sort of upper limit. The graph below highlights the opposing curves of PTC and NTC thermistors.

Figure 3: An NTC and PTC plotted on the same chart

What are Thermistor Curves and Ranges?

Apart from the two distinct categories of NTC and PTC, thermistor types differ by curve and range. Overall, they are typically identified by their resistive capacity at 25℃. We’ve already briefly mentioned the common 10K thermistor, for example. It resists 10,000 ohms of current when the ambient temperature is 25℃. There are 3K thermistors, 12K thermistors, 100K thermistors; and the list could go on and on. The 10K thermistor might be a common standard but there countless other thermistors out there that are more precise to use for other specialized tasks. Let’s take a look at the graph of a few different NTC-type thermistors and discuss a couple of significant points.

Figure 4: A comparison of a few NTC thermistors

From these plotted curves, you can tell the optimal range of a thermistor. Take a look at the area below 0℃. Here you can see a large change in resistance but little change in temperature. This means that each tiny increase in temperature can be precisely measured because the resistance change is large and easily measured. Thermistors don’t automatically operate better the colder it is; there is a lower limit to their usefulness. Below temperatures of -50℃, the resistive capacity of most thermistors is too excessive without specialized monitoring and circuitry.

Let’s look at the other end of the chart; the curves above 50℃. There is little change in resistance but large changes in temperature in this section. The curve is relatively flat. That means it is easy to get inaccurate temperature readings because the resulting resistance changes are so small. You’ll need a very precise instrument to measure the minute changes in resistance otherwise it will seem like your temperature is swinging wildly around. Only specialized thermistors can operate accurately above 100℃.

Want to learn a little more about the practical side of thermistors? Head on over to “What are Thermistors used for?” and we’ll discuss some real-world examples of the niche temperature-sensing market where thermistors operate.

And That’s Thermistors in a Nutshell

Temperature measurement is a widespread requirement throughout a variety of industries and thermistors are an appropriate option for some of those needs. Overall, there is a trifecta of process control temperature sensing instruments available, each with their own strengths and weaknesses. Be sure to read up on RTDs and thermocouples; together with the thermistor, they are the key to our modern temperature sensing processes. Keep your intake of knowledge going and check out “What is a Thermocouple” and “How do RTD Temperature Probes Work?” for more on those other types of temperature sensors.