Thermocouple Wire: A Basic Guide

There are a lot of options when it comes to thermocouple design; we’ve gone through a couple of considerations already in “Guide to Choosing a Thermocouple Junction and Type.” For this blog, we’ll discuss all sorts of aspects related to thermocouple wire. There are hundreds of choices when it comes to picking the right thermocouple wire. However, with a little background information, you’ll be well equipped to choose the type most suitable for your need.

What Type of Thermocouple Wire should I get?

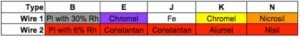

The first place to start when choosing thermocouple wire is to verify what thermocouple type you want. This could be J, K, B, or something else. Thermocouple wire is colour-coded by type. Just by looking at the coating of the two wires, you can tell what the thermocouple type it will be. For example, if you need a J-type thermocouple, a pairing of constantan and iron, you’ll want to use the red-white thermocouple wire to go with it. Constantan makes up the red wire; the white wire is iron. Every standard thermocouple type has a universally accepted standard colour pair.

Figure 1: Thermocouple wire colour chart

The wire where your measurement junction will be is called “thermocouple grade” wire. It is high-grade wire that accurately portrays the characteristics of the two different composition metals when the thermocouple is heated or cooled. After that, there is “extension grade” wire, which is simply a cheaper version of thermocouple grade wire, both in price and quality. Depending on your process, you may need only a short length of wire and use all thermocouple grade material. However, some processes require long runs of wire. In those cases, one would use a small amount of initial thermocouple grade wire then attach the cheaper extension grade wire to run the remaining distance to the control that would be reading the voltage sensed by the instrument. It is of the utmost importance to match the correct colour-coded wires.

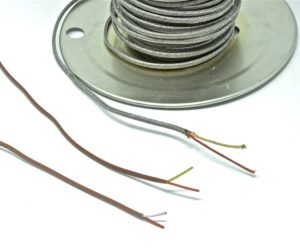

Figure 2: A selection of J and K-type thermocouple wire

As you notice in Figure 2, another option to consider is the material that surrounds and protects the two thermocouple wires housed inside. PVC coated wire is flexible and resistant to UV, water, and chemicals, but can only withstand temperatures of up to 100ºC before it degrades. Teflon-coated wire is an alternative to PVC and can withstand temperatures up to 200ºC. Other types, such as aluminum or stainless steel coated wire, can mitigate interfering electronic noise and be extremely durable.

These benefits, however, will come at a higher price point. Those are just a few of the many different available options. But how do you choose your wire coating? Every job is different, but there is an ideal wire out there to use; when you consider the environment that the thermocouple and any extension wire will be in. When deciding on thermocouple wire, several factors play a role. Such as, the cost, ambient temperature, amount of foot traffic, and even how much the thermocouple itself will be handled or manipulated are all factors that should be considered.

How does a Thermocouple plugin?

A lot of effort goes into talking about thermocouple types, junctions, and wire, but how does a thermocouple end? Your thermocouple will likely connect to a PLC, or Programmable Logic Controller. This is just a computer that is tailored towards manufacturers or industrial users for automation, data monitoring, or building management. A PLC will process the measured voltage from a thermocouple and act on the information. Here are a few ways a thermocouple will connect to a PLC.

Figure 3: Various termination options for a thermocouple

Thermocouple Wire

If you recall, in the previous section, we discussed extension grade wire as a cheaper version of thermocouple grade wire. In an ideal situation, one could run 1000 feet of extension wire, or more, without much concern. However, this leaves your thermocouple end as two bare wires, making the act of connecting your thermocouple to a PLC more complicated. Therefore, special tools or workforce installation training may be required. For complex systems you may even need to hire a certified installer.

This can become a big issue; the more often a thermocouple needs replacement. Also, long lengths of thermocouple wire are susceptible to electrical “noise” or interference from other electricity-using operations that are occurring nearby—presenting a risk of altering the thermocouple voltage measurement and giving you a false temperature reading. We’ve discussed a mitigation option, wire shielding, earlier, but there is an alternative option, signal transmitting, that is featured below.

Figure 4: Bare thermocouple wires getting fastened into circuitry

Connectors

An alternative to bare wire ends is a thermocouple connector. These connectors consist of a male plug and a female receiver pair and can be placed anywhere along your thermocouple wiring. With these connectors, you can join extension grade wire to thermocouple grade wire, or connect two lengths of extension wire to make it into one long piece. These make it incredibly easy to swap out worn thermocouples. So you don’t have to fumble around with wiring; hire an electrician, or shut down your whole manufacturing process just to change a single temperature sensor. Each connector is specific to a type of thermocouple and is composed of the same two different metals, so there is no concern to accuracy loss or affecting the measured voltage.

Figure 5: Thermocouple K-type connectors

Head

The final option for the end of your thermocouple is what is known as a head. These heads provide a protected area for terminal connections, a universal need for many temperature sensors. Thermocouples, RTDs, or thermistors can all be used with a head. Within the protective head of a thermocouple, the two dissimilar wires can be securely connected. This can be to extension grade wire via loose ends, a terminal block for simplified wiring, or even those connectors that we talked about just a minute ago.

Figure 6: Head with a terminal block and a T-type thermocouple

Transmitters can also be mounted inside your head. These devices will take the voltage measured by the thermocouple and translate it into a 4…20mA signal. By changing the voltage data into an analog current standard a thermocouple can be directly integrated into many different process control systems without having to go through a PLC first; or if a system cannot understand the millivolt output of a thermocouple but can understand the electrical current language of the analog standard. We have a whole blog about “What is an Analog Signal” so check that out for a full review of potential benefits from using this transmission option for your thermocouple. You can also visit the product page for Enercorp’s thermocouple transmitter, the TXP420, where you can review the specs on this versatile option.

Figure 7: A TXP420 transmitter in a head with a T-type thermocouple

Heads come in many different types. The size of the head varies based on the available space and how rugged it needs to be. Materials used to make heads are equally varied and depend on the environment it will be used in. Aluminum is a lightweight and sturdy material, but even sturdier are cast iron heads. Polypropylene plastic heads are easy to sanitize and are resistant to chemicals. But stainless steel heads are a more durable alternative to consider as well. Heads will have caps to allow access to wiring, and usually two other openings. One is for a process and the other is a conduit to allow for output wiring.

Figure 8: A variety of heads

Along with our other blog “Guide to Choosing a Thermocouple Junction and Type“ we’ve offered up all sorts of info on the things to consider when designing a thermocouple. Don’t worry, at Enercorp we will walk you through some of the design options. But these discussions give you an idea of the different aspects that will affect how your custom thermocouple is built. Why not inform yourself further on this amazing temperature sensor and visit “What is a Thermocouple?”